News

Stay informed

Every day, Transocean Coatings products are applied to ships and structures in countries around the world. Stay informed about our projects and the Transocean Coatings association as a whole, through this news page and our social media accounts on LinkedIn and Instagram.

All smiles at Transocean Coatings

Handshake between Waling Dijkstra and Bart Martens to confirm management change at Transocean Coatings

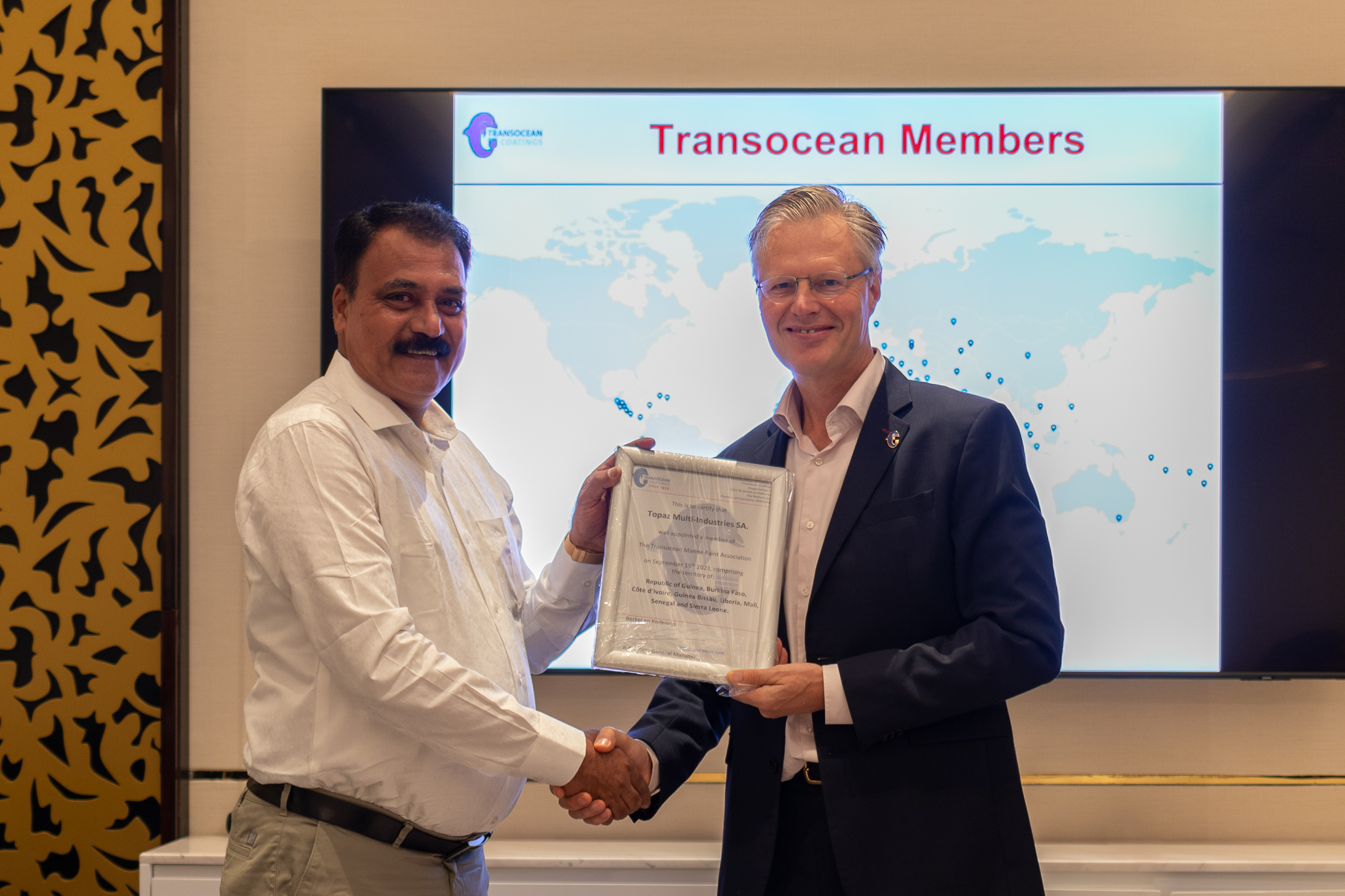

Transocean Coatings expands in Africa

Founded in 1995 in Conakry, Guinea, the Topaz Group is now joining the Transocean Coatings association to support their vision to become the leading plastics and paint company …

Certified products for Jet fuel storage

Transocean Coatings epoxy linings selected from Transpoxy Novacure and Tankguard ranges, EI-1541 approved for use in Jet Fuel storage tanks