About ISO 12944

Selecting protective coating systems using ISO 12944

Protective coatings for steel are seen everywhere, from structural steel in buildings, internal and external roof construction, bridges, storage tanks and pipes for our water and fuel infrastructure, industrial structures in factories and off-shore as parts of renewable energy or oil and gas assets. And then there are the invisible parts: buried, immersed or seldom seen internal parts, tidal and splash zones.

Together these possible scenarios form the environment parameters described in the widely used ISO 12944 standard “Paint and Varnishes: Corrosion Protection for steel structures by protective paint systems”.

The challenge of finding the right protective coatings is reduced understanding this standard and using tested and certified Transocean Coating solutions.

Introducing exposure & durability

In short, the ISO 12944 standard proposes coating systems for carbon steel and galvanized steel depending on exposure conditions. It also includes a list of laboratory tests to confirm suitability of coating systems, more on the that further down on this page.

Where coated steel is used, i.e. what corrosive environment it will be exposed to, has a major influence on how long a coating system will last: the durability. In the standard, durability dictates coating type and the minimum film thickness. In ISO 12944, four ranges of durability are used as period to first major maintenance:

- low (L) <7 years

- medium (M) 7-15 years

- high (H) 15-25 years

- very high (VH) >25 years

On-shore and off-shore

Since the first version in the late 1990s, the main use of ISO 12944 probably has been for on‑shore atmospheric corrosion protection. The environmental or corrosivity categories that go with this exposure scenario are going from light to severe: C1, C2, C3, C4 & C5 as described in the first table below.

There are a number of non-atmospheric service categories: in fresh water, in salt/brackish water and buried as shown in the second table. Three off-shore environments were added to the ISO 12944 standard in 2018: atmospheric (CX), immersion with cathodic protection (Im4) and splash zone (a combination of CX and Im4 with its own set of thickness specifications).

After coating selection, it is up to for contractors,

applicators and those involved in quality control to get the most out

of the coating system. There are parts to the ISO 12944 standard

focussing on the application phase that can assist with this. The impact

of this part of the process should not be overlooked.

The different parts of the ISO 12944 standard, including the full film thickness tables can be bought from local standardisation organisations or the ISO website.

ISO 12944-2 exposure categories

| Atmospheric Corrosion category | Steel loss after 1st year of exposure | Examples Exterior | Examples Interior |

| C1 (very low) | ≤ 1,3 µm | – | Heated buildings in rural areas such as offices, hotels, public buildings |

| C2 (low) | > 1,3 – 25 µm | Rural areas with low level of pollution. | Unheated buildings where condensation may occur such as warehouses. |

| C3 (medium) | > 25 – 50 µm | Urban and industrial areas with moderate sulphur dioxide pollution. Coastal areas with low salinity. | Industrial facilities with high humidity such as food processing industries, breweries. |

| C4 (high) | > 50 – 80 µm | Industrial and/or coastal areas with moderate salinity. | Chemical plants, swimming pools, boat yards, ship interiors. |

| C5 (very high) | > 80 – 200 µm | Industrial areas prone to high humidity and chemical attack. Coastal areas with high salinity. | Facilities exposed to permanent condensation and chemicals. |

| CX (extreme) | > 200 – 700 µm | Offshore areas with high salinity. Industrial areas exposed to extreme humidity, aggressive atmosphere and tropical areas. | Facilities exposed to extreme humidity and aggressive atmosphere. |

| Corrosion category | Environment | Examples of environments and structures |

| Im1 | Fresh water | River installations, hydro-electrical power plants |

| Im2 | Sea or brackish water | Immersed structures without cathodic protection (e.g. harbour areas with structures like sluice gates, locks or jetties) |

| Im3 | Soil | Buried tanks, steel piles, steel pipes |

| Im4 | Sea or brackish water | Immersed structures with cathodic protection (e.g. offshore structures) |

Coating Selection

In the ISO 12944 standard, coating systems are proposed based on expected exposure (corrosivity) and a required durability range. The dry film thickness (DFT) tables are based on different coating technologies. Systems descriptions may not be available for all combinations of durability and corrosion category. For instance for the immersion or Im 1-3 specifications , only H and VH are proposed. More frequent maintenance would not be economically viable in such scenarios.

The specified film thickness goes up with durability requirements and the aggressiveness of the environment. Stepping up a corrosion category and down a durability class generally results in the same DFT requirements, for example: a system for C3-high (C3 H) will be the same as for C4-medium (C4 M).

The tables for CX, Im4 and splash zone protective coating systems specify systems that should give a high (15-25 years) durability (no other durability ranges are included for the offshore scenarios).

Film thickness table for atmospheric systems (see ISO 12944-5)

| Durability | Low (l) | Medium (m) | High (h) | Very high (vh) | |||||||||

| Type of primer 1 | Zn(R) | Misc | Zn(R) | Misc | Zn(R) | Misc | Zn(R) | Misc | |||||

| Binder chemistry of primer 1 | ESI, EP, PUR | EP, PUR, ESI | AK, AY | ESI, EP, PUR | EP, PUR, ESI | AK,AY | ESI, EP, PUR | EP, PUR, ESI | AK,AY | ESI, EP, PUR | EP, PUR, ESI | AK,AY | |

| Binder chemistry of subsequent coats | EP, PUR², AY | EP, PUR², AY | AK, AY | EP, PUR², AY | EP, PUR², AY | AK, AY | EP, PUR², AY | EP, PUR², AY | AK, AY | EP, PUR², AY | EP, PUR², AY | AK, AY | |

| C2 | Number of Coats | – | – | – | 1 | 1 | 1 | 1 | 2 | 2 | 2 | ||

| Dry Film Thickness | Note 3 | – | – | 100µm | 60µm | 120µm | 160µm | 160µm | 180µm | 200µm | |||

| C3 | Number of Coats | – | – | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | – |

| Dry Film Thickness | – | – | 100µm | 60µm | 120µm | 160µm | 160µm | 180µm | 200µm | 200µm | 240µm | – | |

| C4 | Number of Coats | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 2 | – |

| Dry Film Thickness | 60µm | 120µm | 160µm | 160µm | 180µm | 200µm | 200µm | 240µm | 260µm | 260µm | 300µm | – | |

| C5 | Number of Coats | 2 | 2 | – | 2 | 2 | – | 3 | 2 | – | 3 | 3 | – |

| Dry Film Thickness | 160µm | 180µm | – | 200µm | 240µm | – | 260µm | 300µm | – | 320µm | 360µm | – | |

Note 1: Zn(R)= zinc-rich, Misc. = miscellaneous primer, see text, ESI = zinc silicate, EP = epoxy, PUR = polyurethane, AK = alkyd, AY = acrylic (mainly water based)

Note 2: in addition to polyurethane technology, other coating technologies may be suitable, e.g. polysiloxane, polyaspartic and fluoropolymer

Note 3: if a coating is desired (for C2-low), use a system for higher corrosivity category or durability, e.g. C2-high or C3-medium

This is a simplified version of the table in ISO12944 part 5. Number of coats should be read as a minimum. For dry film thickness (DFT) the standard talks about ‘nominal’ DFT. For exact definitions please refer to the standard.

Coating system requirements for Im1, Im2 and Im3 in line with ISO 12944-5

| Durability | High | Very High | ||||

| Type of primer 4 | Zn(R) | Misc. | n/a (single coat) | Zn(R) | Misc. | n/a (single coat) |

| Binder chemistry of primer 4 | ESI, EP, PUR | EP, PUR | – | ESI, EP, PUR | EP, PUR | – |

| Binder base of subsequent coats | EP, PUR | EP, PUR | EP, PUR | EP, PUR | EP, PUR | EP, PUR |

| Minimum number of coats | 2 | 2 | 1 | 2 | 2 | 1 |

| Dry Film Thickness | 360µm | 380µm | 400µm | 500µm | 540µm | 600µm |

Note 4: Zn(R)= zinc-rich, Misc. = miscellaneous primer, ESI = zinc silicate, EP = epoxy, PUR = polyurethane

Coating system requirements for CX, Splash and Tidal Zones and Im4 in line with ISO 12944-9

| Type of Environment | CX (offshore) | Splash and tidal zones CX (offshore) and Im4 | Im4 | ||||

| Type of primer | Zn(R) | Other primers | Zn(R) 5 | Other primers | Other primers (single coat) | ||

| Primer Dry Film Thickness | ≥40µm | ≥60µm | ≥40µm | ≥60µm | ≥200µm | – | ≥150µm |

| Minimum number of coats | 3 | 3 | 3 | 3 | 2 | 1 | 2 |

| Dry Film Thickness of full paint system | ≥280µm | ≥350µm | ≥450µm | ≥450µm | ≥600µm | ≥800µm | ≥350µm |

Note 5: This coating system with an organic Zn(R) primer can also be used for IM4 service if a Zn(R) primer is desired. In this case the thickness of the complete system van be reduced to ≥350µm.

Primers: Zinc or no Zinc?

In most system descriptions in the standard, there is a choice to use a zinc-rich primer (abbreviated to “Zn(R)” primer). The definition for this type of primer comes down to a minimum of 80% zinc dust pigment by weight in the dry film. Transocean Coatings offers 3 types of zinc rich primers: zinc silicate, zinc epoxy and (moisture cured) zinc polyurethane primers.

All other primer types, including those containing zinc below 80%, are considered “miscellaneous” primers for part 5 or described as “other primers” in part 9 of the standard. A note is made indicating there are local standards that require higher amounts of zinc for a coating to be called a zinc or zinc-rich product and used in certain specifications (for example the zinc-silicate specification in Norsok M-501 (rev.7)).

Examples

Primers that have been used in coating systems that have passed ISO 12944-6 and/or 9 testing:

- Transozinc Silicate 147 (TO 1.47) complies with ISO 12944 Zinc Rich, as well as with SSPC-20 Type I, Level 2 (≥77% zinc)

- Transozinc Silicate (TO 1.52) complies with ISO 12944 Zinc Rich, as well as with SSPC-20 Type I, Level 1 (≥85% zinc)

- Transozinc Epoxy Primer 155 (TO 1.55) complies with ISO-12944 Zinc Rich, as well as SSPC standard Paint 20, Type II, level 1 (≥85% zinc)

- Transpoxy Uniprimer (TO 1.71), Transpoxy Masterbond BT (TO 4.68) and Transpoxy Masterbond Alu 466 (TO 4.66) are non-zinc epoxy primers (miscellaneous or other primers in ISO 12944)

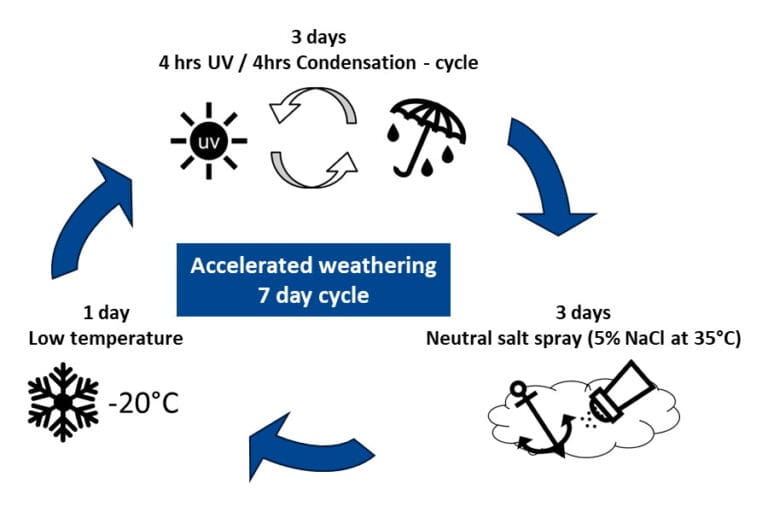

Tested and certified coating systems

| Environment | Test Duration |

| C4VH / C5H | 1680h = 10 weeks |

| C5VH | 2688h = 16 weeks |

| CX and splash-zone | 4200h = 25 weeks |

Certified system examples

Transocean Coatings offers a wide portfolio of products that can be combined to the coating systems as specified by the ISO 12944 standard. Third party testing has resulted in a range of coating systems that are certified to meet the performance requirements of the ISO 12944 standard from C3 to CX environments and different durability ranges. Contact your local Transocean Coatings representative for more information on availability.

| Exposure | Durability | Substrate | Primer type | Product | DFT | 2nd coat | DFT2 | 3rd coat | DFT3 | Total DFT |

| C2 | H | CS (Sa 2½)(1) | Misc. epoxy | Transpoxy Masterbond 467 (TO 4.67) | 120µm | – | – | – | – | 120µm |

| C3 | H | CS (Sa 2½)(1) | Misc. epoxy | Transpoxy Unicote (TO 4.32) | 150µm | Transurethane Shield (TO 3.45) | 70µm | – | – | 220µm |

| C4 | H | CS (Sa 2½)(1) | Misc. epoxy | Transpoxy Masterbond Alu 466 (TO 4.66) | 100µm | Transpoxy Masterbond (TO 4.67) | 100µm | Transurethane Finish (TO 3.43) | 40µm | 240µm |

| C5 | H | CS (Sa 2½)(1) | Zn(R), epoxy | Transozinc Epoxy Primer 155 (TO 1.55) | 60µm | Transpoxy Masterbond (TO 4.67) | 160µm | Transurethane Finish (TO 3.43) | 40µm | 260µm |

| C5 | VH | CS (Sa 2½)(1) | Zn(R), silicate | Transozinc Silicate 147 (TO 1.47) | 90µm | Transpoxy Masterbond BT (TO 4.68) | 90µm | Transpoxyl PX 370 (TO 3.70) | 80µm | 260µm(2) |

| CX-Im4 | H(3) | CS (Sa 2½)(1) | Zn(R), silicate | Transozinc Silicate 147 (TO 1.47) | 85µm | Transpoxy Masterbond BT (TO 4.68) | 120µm | Transpoxyl PX 370 (TO 3.70) | 75µm | 280µm(2) |

(1) Carbon steel, abrasive blasting to Sa2½ (ISO 8501), see product datasheet of primer for more details on profile requirements

(2) DFT the system was tested at, specification table in ISO 12944 may require higher thickness

(3) systems in ISO 12944-9 for CX and Im4 are designed for high durability only, no very high durability systems are described in this part of the standard

For more information about ISO 12944, download our “Guide to protective coating selection using ISO 12944″.

In this guide we indicate how anyone can select a suitable coating system for steel protection using a the parameters described in the above: environment, durability, primer and system type selection followed by testing.

For datasheets and information about the mentioned products go to the Products page.